3D Printers

EOS Formiga P110

Techonology: SLS (selective laser sintering)

Specifications: Technology that makes it possible to print parts with complex geometries having organic shapes without requiring the use of support materials. SLS technology is precise, fast, and outperforms other technologies given its print volume and the ability to manufacture multiple parts in a single print.

Maximum part dimensions: 200 mm x 250 mm x 300 mm

Materials: Various polymers such as TPE, polyamide and aluminum

AON3D M2

Technology: FDM (fused deposition modeling) high temperature

Specifications: Dual independent tool heads allow you to design parts using multiple materials, such as soluble supports materials, or quickly switch between two different nozzle sizes. Its two independent print heads, both in temperature and movement, also offer the possibility of co-extrusion. It would therefore be possible to have a part with a flexible portion and a rigid portion.

Maximum part dimensions: 450 mm x 450 mm x 640 mm

Materials: This printer is designed to print thermoplastics with particular grades: PEEK, PEKK, Ultem, etc.

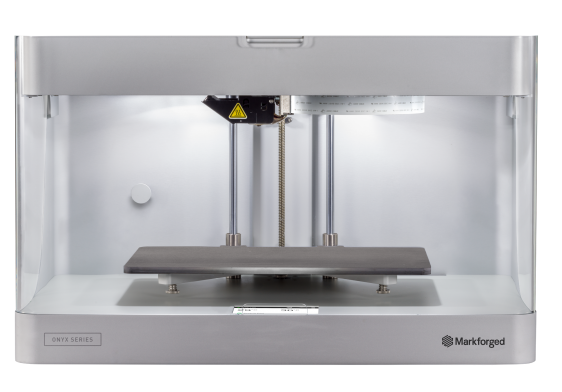

Markforged Onyx One

Technology: FDM (fused deposition modeling)

Specifications: 3D printer for manufacturing precise parts both in dimensional and geometric terms. This machine uses fused deposition modeling technology and more precisely with a material called onyx, a polyamide (PA6) reinforced with micro carbon fiber.

Maximum part dimensions: 320 mm x 132 mm x 154 mm

Materials: Onyx (PA6) reinforced with micro carbon fiber

Markforged Mark Two

Technology: CFF (continuous fiber fabrication)

Specifications: 3D printer allowing the manufacture of precise parts both in dimensional and geometric terms. Like its little sister, the Onyx One, this machine uses fused deposition modeling technology, but allows the use of a wider variety of polymers in addition to offer continuous fiber reinforcement process during printing to modify its mechanical, physical and thermal properties.

Maximum part dimensions: 320 mm x 132 mm x 154 mm

Materials: Onyx (PA6 reinforced with carbon fiber), nylon (PA6), carbon fiber, Kevlar fiber, fiberglass, high temperature and high resilience fiberglass.

Markforged X7

Technology: CFF (continuous fiber fabrication)

Specifications: In addition to having the same characteristics as its two little sisters, this 3D printer has a larger print volume as well as a dimensional and geometric laser inspection scan allowing, among other things, to have a constant monitoring on printing progress.

Maximum part dimensions: 330 mm x 270 mm x 200 mm

Materials: Onyx (PA6 reinforced with carbon fiber), nylon (PA6), carbon fiber, Kevlar fiber, fiberglass, high temperature and high resilience fiberglass.

Markforged Metal X

Technology: ADAM (atomic diffusion additive manufacturing)

Specifications: This set of equipment has the ability to fabricate complex parts from metallic materials. It consists of a printer, a solvent-based debinding system and a tube furnace which together give impeccable results in various metals.

Maximum part dimensions: 250 mm x 183 mm x 150 mm

Materials: Stainless steel (14-4 PH), copper, Inconel 625, tool steel H13, A2 and D2

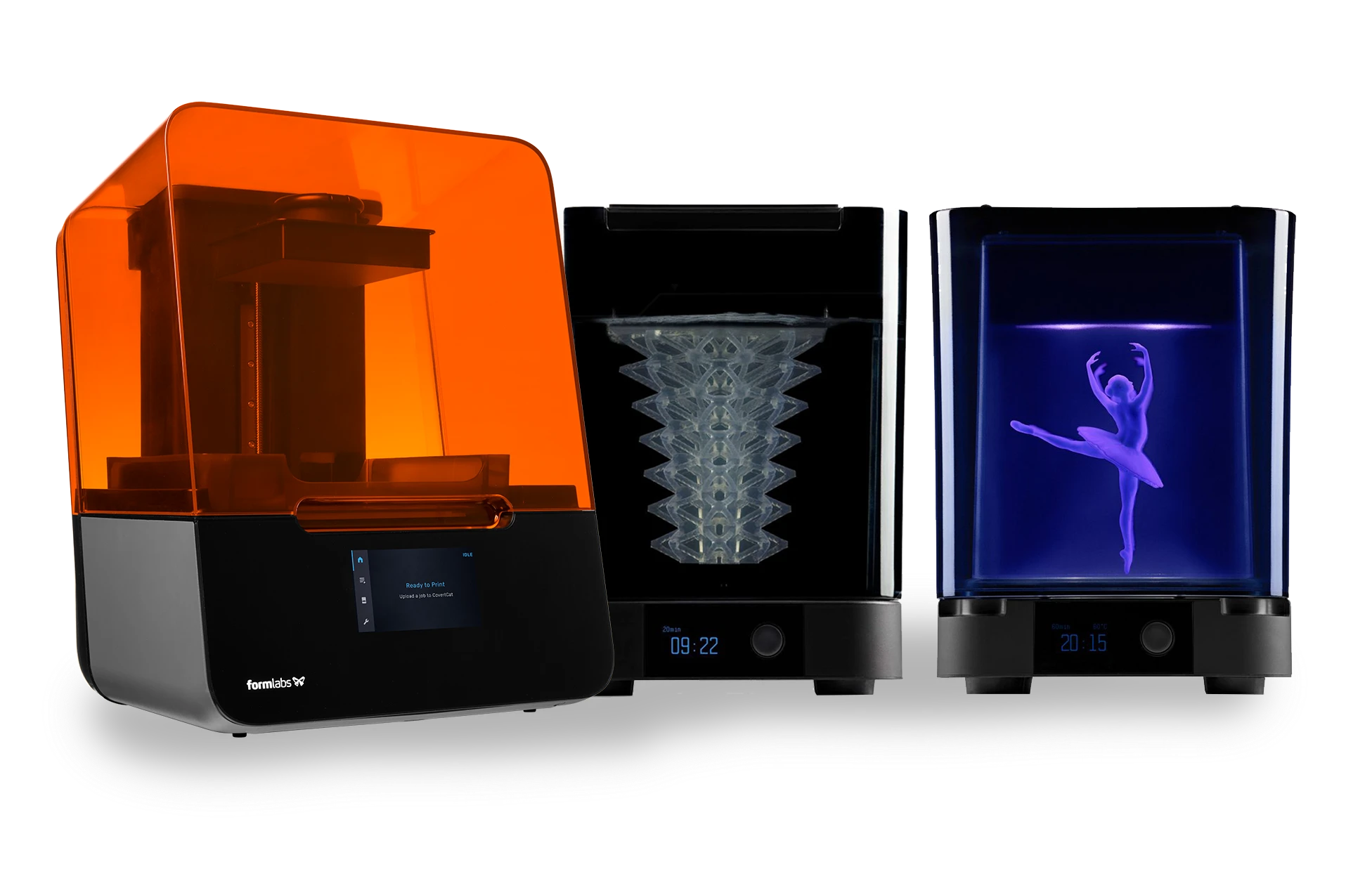

Formlabs Form 3

Technology: LFS (low force stereolithography)

Specifications: A trio of additive manufacturing equipment offering a complete solution from printing to parts cleaning and post-cure. In the form of liquid photopolymer resins, the materials are offered in different hardnesses, colors and mechanical properties.

Maximum part dimensions: 145 mm × 145 mm × 185 mm

Materials: Photopolymer resins

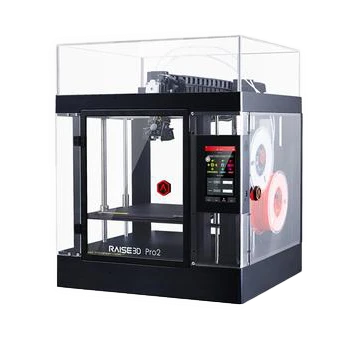

Raise 3D Pro2

Technology: FDM (fused deposition modeling)

Specifications: Fused filament deposition 3D printer with dual independent temperature nozzles, which offers the option of printing two materials at the same time or using support material to facilitate the printing process.

Maximum part dimensions: 305 mm x 305 mm x 300 mm

Materials: Rigid or flexible polymer filaments

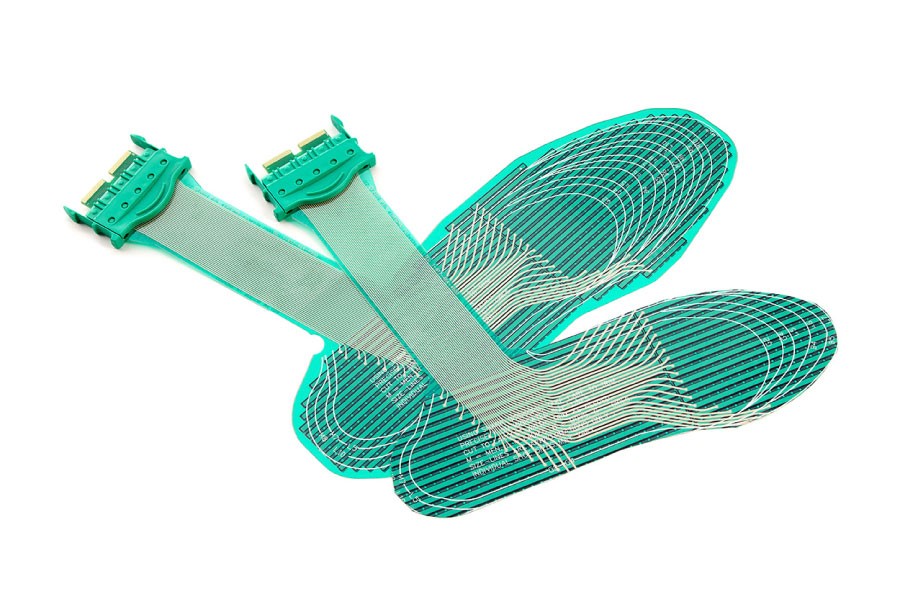

Arkad Printer

Technology : FDM (fused deposition modeling)

Specifications : Printer that offers the possibility of continuous printing. Up to 100 pairs of insoles can be produced without human intervention. It is possible to choose among 17 density adapted to each area of the insoles, thanks to the Arkad soft software.

Maximum part size : Allows printing of insoles up to 50 mm high.

Matériaux : Arkad Printer TPU Spool

Milling Machines

Rodin 4D Milling Machine - Model S

Fast, efficient and versatile, the Rodin 4D computer controlled milling machine is a piece of equipment specializing in machining positives for proper thermoforming.

Material used: Polyurethane foam

Maximum dimensions of the milling block: 700 mm x 500 mm

Isel ICP 4030 – Revision Orthodutch

This CNC milling machine is specialized in the field of plantar orthosis. This machine has been revised by the firm Orthodutch in order to be able to mill plantar orthotics in record time, without generating polyurethane foam damage during machining. It is also able to machine in soft and hard non-metallic materials.

Materials used: polyurethane foam, wood, plastics, prototyping foam, etc.

Maximum dimensions of the milling block: 400 mm x 305 mm x 140 mm

Roland DGA Modela MDX-50

This high precision CNC milling machine has great capabilities regarding dimensional and geometric precision during mass production of parts. Can be paired with a fourth axis, a rotating head as a machining plate, TOPMED is now able to quickly machine any type of mold or complex parts.

Materials used: polyurethane foam, wood, plastics, prototyping foam, etc.

Maximum dimensions of the milling block: 400 mm x 305 mm x 135 mm

Vorum Milling Machine

With a rotating axis and a flat carving surface, the 4-axis cutting machine is the solution to your various manufacturing needs for orthopedic seats and insoles in addition to a wide range ot orthopedic and prosthetic models.

Material used : eva polyurethane foam, cork

Maximum milling volume : one seat or 8 pairs of insoles

Metrology and Mechanical Tools

Hexagon Absolute Arm, 8520, 7-Axis, RS6 Kit

Usefulness: Metrology (dimensional and geometric control)

Specifications: Instrumented measuring arm allowing tactile probing and non-contact scanning on a multitude of parts. Working in conjunction with a laser scanner and ruby probes, it facilitates batch control, device positioning validation, fatigue strain control and more.

Dimensional accuracy: 26 μm

MTS Exceed E42

Usefulness: Mechanical tests

Specifications: Destructive or non-destructive mechanical testing instrument. The Exceed E42 can perform tensile, compression and bending tests, on flexible, semi-flexible or semi-rigid materials such as metals, textiles and polymers. Equipped with a load cell with a capacity of 5000N, it covers the vast majority of tests carried out by the TOPMED team.

Maximum force: 5kN

Across International FO19140

Use: Convection oven for heat treatments

Specifications: Rather common in research laboratories, this convection oven is mainly used in TOPMED premises for heat treatment purposes on parts manufactured by 3D printing in high temperature materials.

PolyDry 3D680

Usefulness: Humidity-controlled Filament Storage Unit

Specifications: Storage units are used in laboratories to store 3D printing materials.

Scanning Tools

Structure Sensor Mark II

TOPMED uses the Structure Sensor Mark II scanner to create high quality 3D patient models for precise adaptation of orthosis and prostheses to the needs of the person.

Creaform

Creaform’s 3D scanner for healthcare organizations is the perfect device for taking 3D body measurements. Scans are used to make personalized devices, therefore, better suited to the needs of the user and more comfortable. It is an excellent choice that can replace traditional methods such as plaster casting.

Scanner Peel 2 3D for orthoses and prostheses

Peel 2 3D is a professional grade portable 3D scanner in its purest form. It doesn't have any unnecessary gimmicks to make it more interesting or attractive. It simply allows you to perform high quality 3D scans of small or large objects. It can scan most of the items directly without any preparation, as it automatically recognizes the shape of objects.

Podiatech PrintLab 2

These are two separate silicone vacuum bags filled with microballs connected to a built-in vacuum pump with filter. The PrintLab 2 allows each foot imprintto be set separately and to obtain better stability during insole molding.

Vorum 3D Plantar Scanner

The Vorum 3D Plantar Scanner is a high-precision optical imaging device. It was designed to capture the three-dimensional shape of the plantar aspect of human feet for the purpose of designing personalized custom insoles.

The 3D data recorded by the scanner is then used with the Canfit software. The production of custom orthotics, orthotic molds or soft insoles can then begin.

Biomechanical Data Acquisition Tools

Vicon Vantage V5

Video acquisition system based on a set of 8 cameras to capture various movements in a laboratory environment. By equipping patients with reflective markers, cameras can locate body segments in space using infrared light.

XSENS MVN LINK

A set of sensors that measure the acceleration and orientation of all segments of the body during movement. The system is portable and is attached with a system of straps on the user or with a suit adapted to movement analysis.

Motorised treadmill MOBIUS‐EI2

AMTI (Advanced Mechanical Technology Inc.)

Motorised treadmill equipped with two force platforms which can be inclined. This equipment makes it possible to measure reaction forces on the ground when walking, running or during any other movement.

Accu-Gait

AMTI (Advanced Mechanical Technology Inc.)

Pairs of force platforms used to measure reaction forces on the ground in 3 dimensions when walking. They have the advantage of being portable.

Accu-Power

AMTI (Advanced Mechanical Technology Inc.)

Pair of force platforms used to measure reaction forces on the ground during walking, running or other movement. These platforms are designed specifically to handle explosive movements.

FP-Stairs

AMTI (Advanced Mechanical Technology Inc.)

Instrumented staircase with two force platforms to measure the forces generated by each foot when going up and down stairs. Each of the supports is distributed over one of the two platforms in order to be able to analyze them separately.

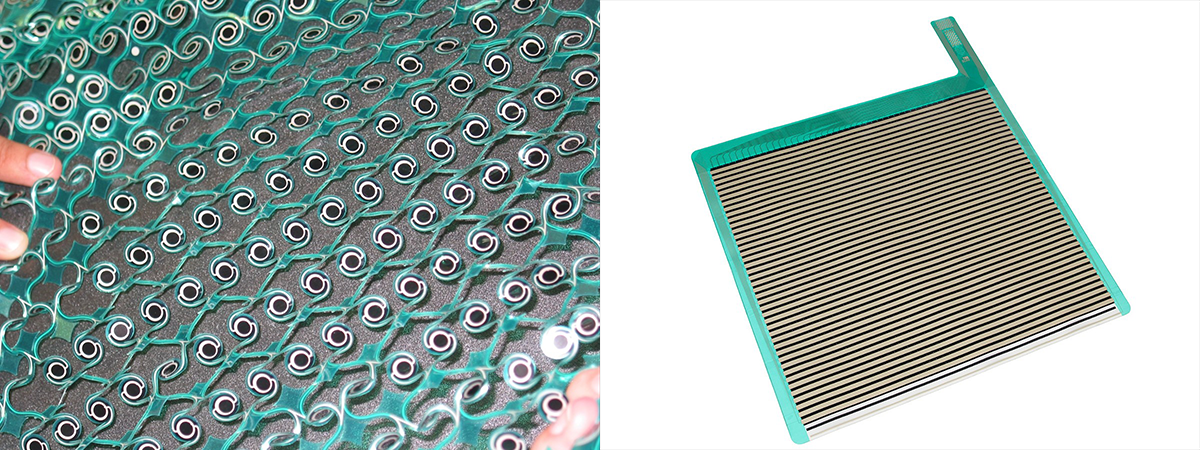

Tekscan Grip System

System of sensors designed to measure dynamic and static pressures on the hands when gripping various objects. Pressure sensors are also used for complex surfaces such as orthotics or prostheses. These are flexible and thin enough to allow for maximal range of movement.

Tekscan F-Scan

Very thin, sole-shaped sensors made to fit into shoes and measure center of pressure during physical activity. They thus allow an analysis of the weight distribution on each support during walking.

Tekscan BPMS

(Body Pressure Matress System)

This system of sensors is useful for measuring the pressure distribution under a person in a sitting or lying position. Relatively thin and comfortable, it fits easily under a pillow, chair or mattress.

BTS Bioengineering FREEEMG 1000

Indispensable tool in the analysis of muscle and nerve activity, the FREEEMG electromyograph has the particularity of being connected to a 4G wireless network. Its sensors can analyze up to 8 muscles simultaneously.

Allied Vision Technologies Mako G-040C

Camera allowing high frequency acquisition of images synchronously with other devices such as the Vicon Vantage V5.

Futek MTA500

MTA500 is a load cell capable of picking up the moments in two axes and the force exerted in a third axis, the axes are mutually perpendicular. The limits of these devices are almost unattainable with human movements, i.e. 45 N/m for torques and the forces are limited to 4,400 N.

Medicapteurs Win-Track

Win-Track is a walking platform measuring 1610 mm by 652 mm that allows you to analyze walking up to 4 consecutive steps. It also collects postural and static data. The platform has 12,288 sensors synchronised at a frequency of 200 images per second (200 Hz) and displays fingerprints in real time.

Software - 3D Division

Materialise Magics

Materialize Magics is a software that simplifies data and build preparation for additive manufacturing. It is used to rectify and parameterize many types of 3D files in order to optimize their production.

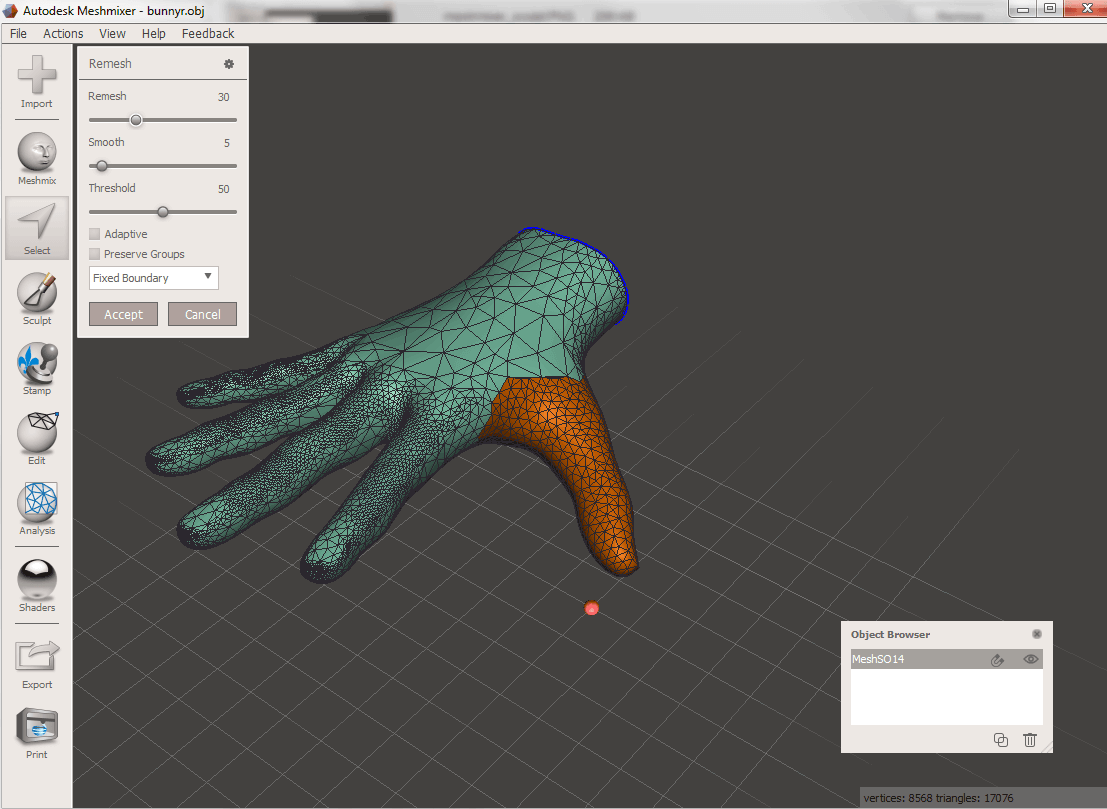

Meshmixer

Meshmixer software is a free product developed by Autodesk® for easy model creation for 3D prints using surface modeling and triangulat mesh. It also allows volume correction with specialized point cloud processing tools. TOPMED uses it to shape or rectify a model quickly for testing and 3D validation.

Software - Orthotics and Prosthetics Division

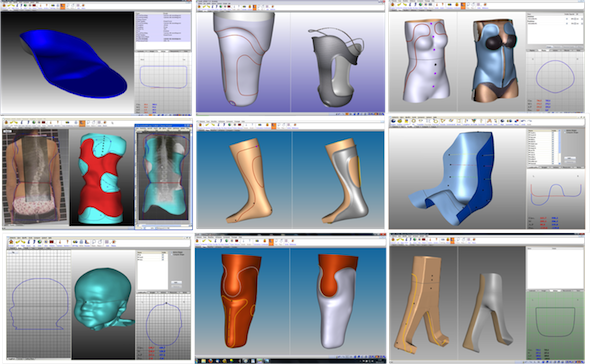

Canfit - CAD/CAM Software

Canfit is a software produced by Vorum allowing to rectify digitized anatomical shapes of all kinds. It is then possible to generate positives for thermoforming thanks to milling or to generate equipment produced by 3D printing.

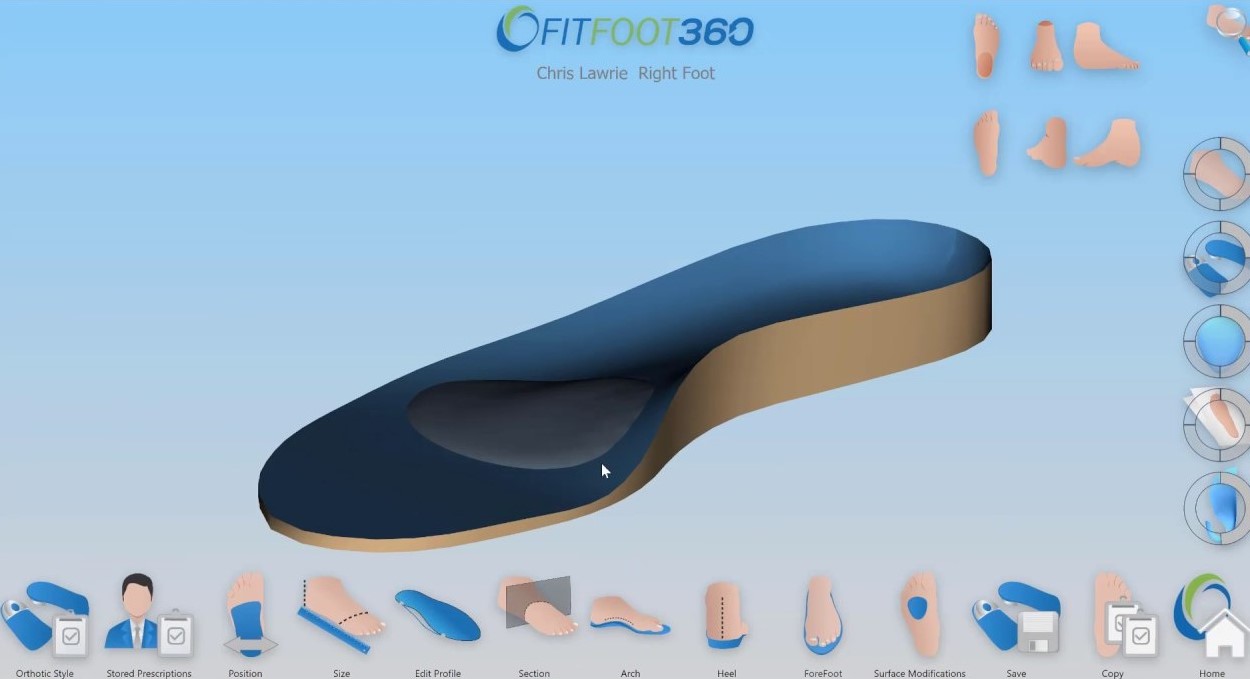

FitFoot 360 - CAD/CAM Software

FitFoot is a logical and intuitive software for digital plantar orthosis design. The modeled orthotics can then be produced using different additive manufacturing or machining technologies.

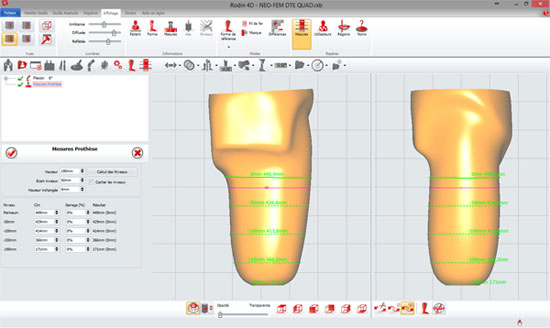

Rodin 4D Neo - CAD/CAM Software

Rodin 4D Néo is a software for rectifying 3D digital form of orthopedic devices. It allows parameterization of their machining in polyurethane blocks in a Rodin milling machine.

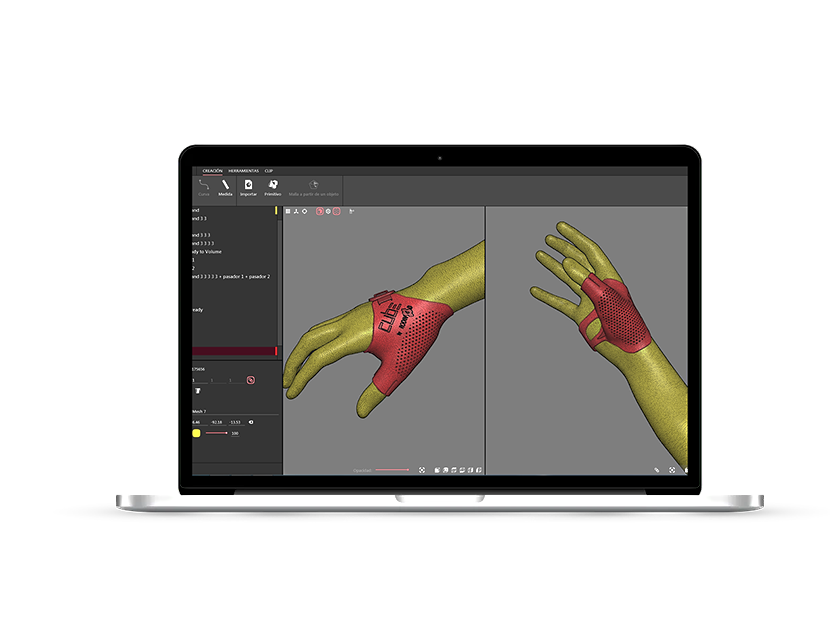

Rodin 4D Cube - CAD/CAM Software

Rodin 4D Cube is a complementary tool to the Rodin 4D Neo software that allows the design of equipment to be taken further thanks to tools specializing in the processing of point clouds. It allows parts with no limitations on form creation to be designed and facilitates preparation for the integration of components.

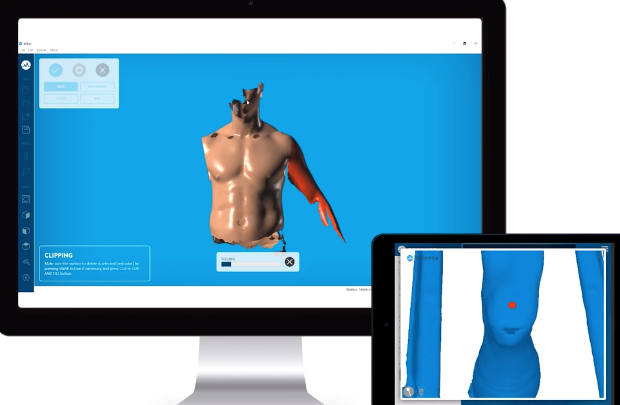

MSoft - 3D Scanning Software

MSoft is a 3D scanning software developed by TechMed 3D. It allows you to quickly and easily obtain 3D files ready to be edited for the design of all kinds of orthopedic devices.

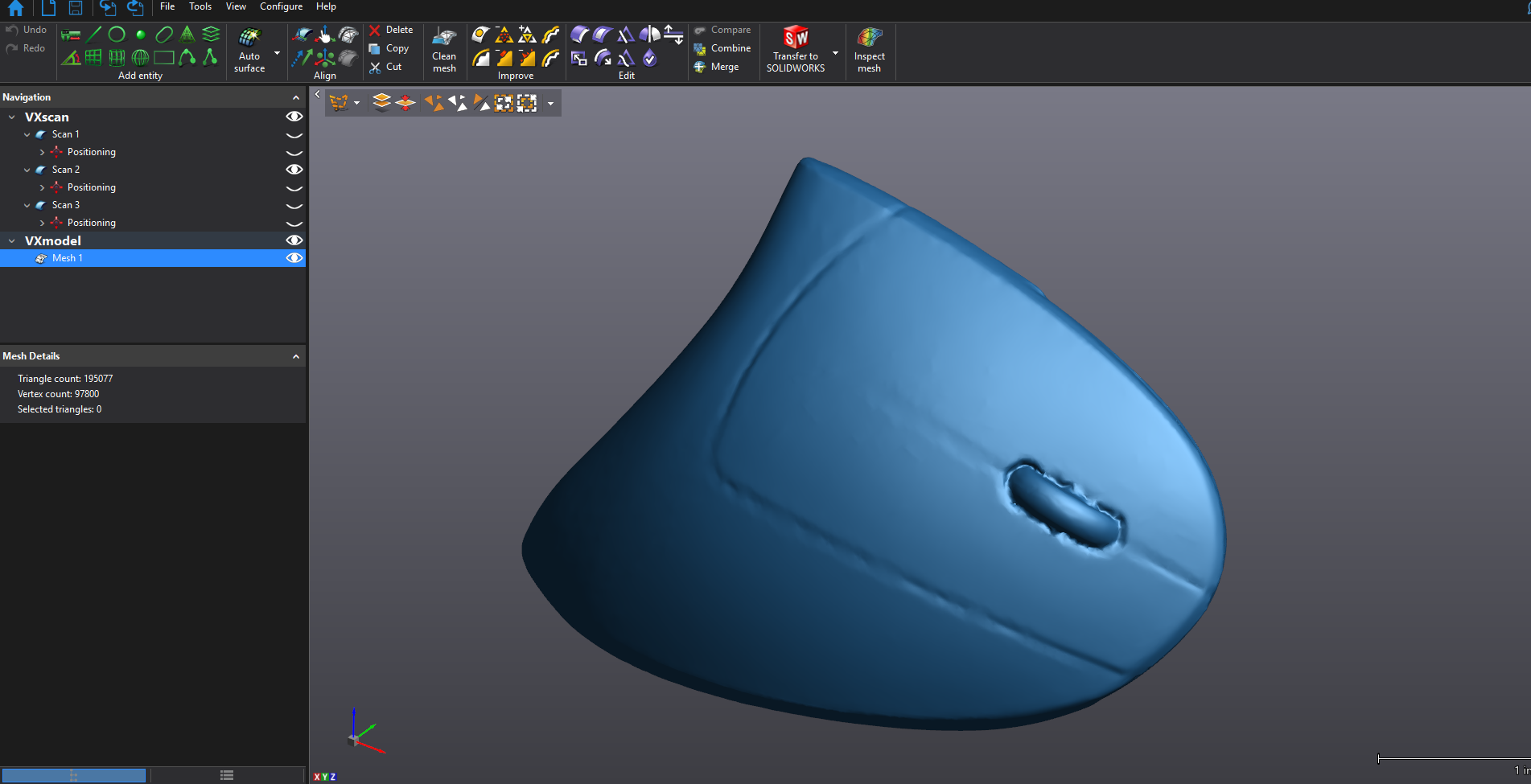

VXscan of VXelement - 3D Scanning Software

It is a software allowing the digitization of objects or anatomical shapes using pulsed light scanning tools. VXscan makes it possible to manage the scan parameters and process the data in order to obtain a 3D file.

Arkad Soft Software

It is a software that design insoles with different design tools, as well as a library of elements and customizable templates. It allows, for example, the adjustment of the heel height and the arch foot modelling.

Software - Mecanic Division

SOLIDWORKS - CAD Software

Through virtual simulation, regulatory data management, and flexible industrial design capabilities, SOLIDWORKS enables the design of innovative and regulatory compliant medical devices.

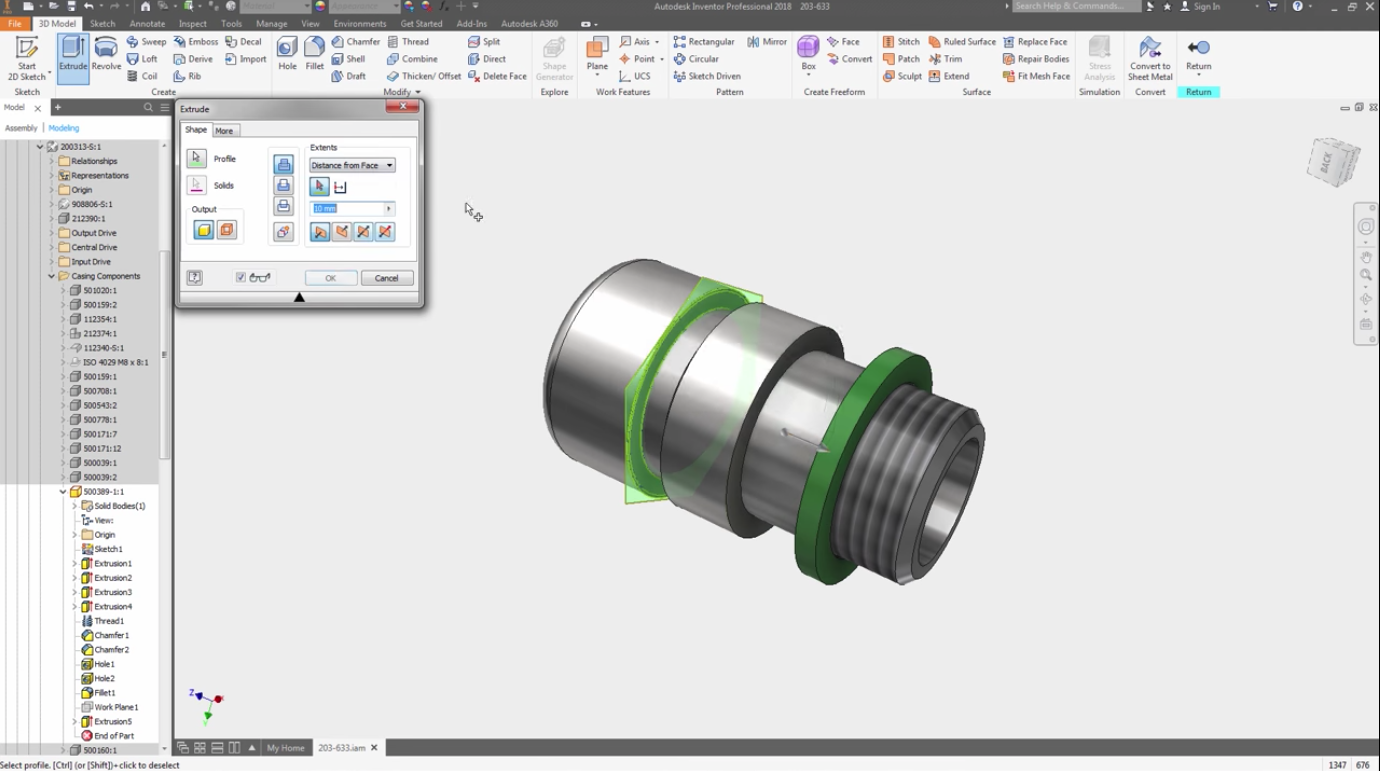

Inventor - CAD Software

lnventor is a 3D modeling software produced by the company Autodesk. It allows efficient use of the parametric design. It is a technical drawing software with a mechanical vocation which is for TOPMED complementary to the SOLIDWORKS suite.

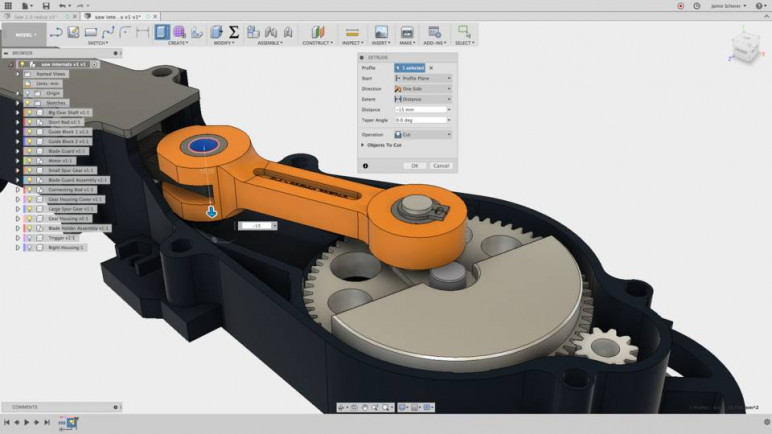

Fusion 360 - CAD Software

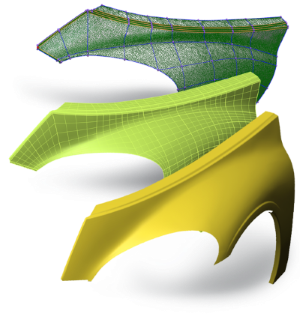

Fusion 360 is a user-friendly and versatile software, which enables the integration of design processes, from design and simulation, to manufacturing. It is a simplified approach to parametric modeling. It is mainly used at TOPMED to generate complex surfaces thanks to its surface modeling tools.

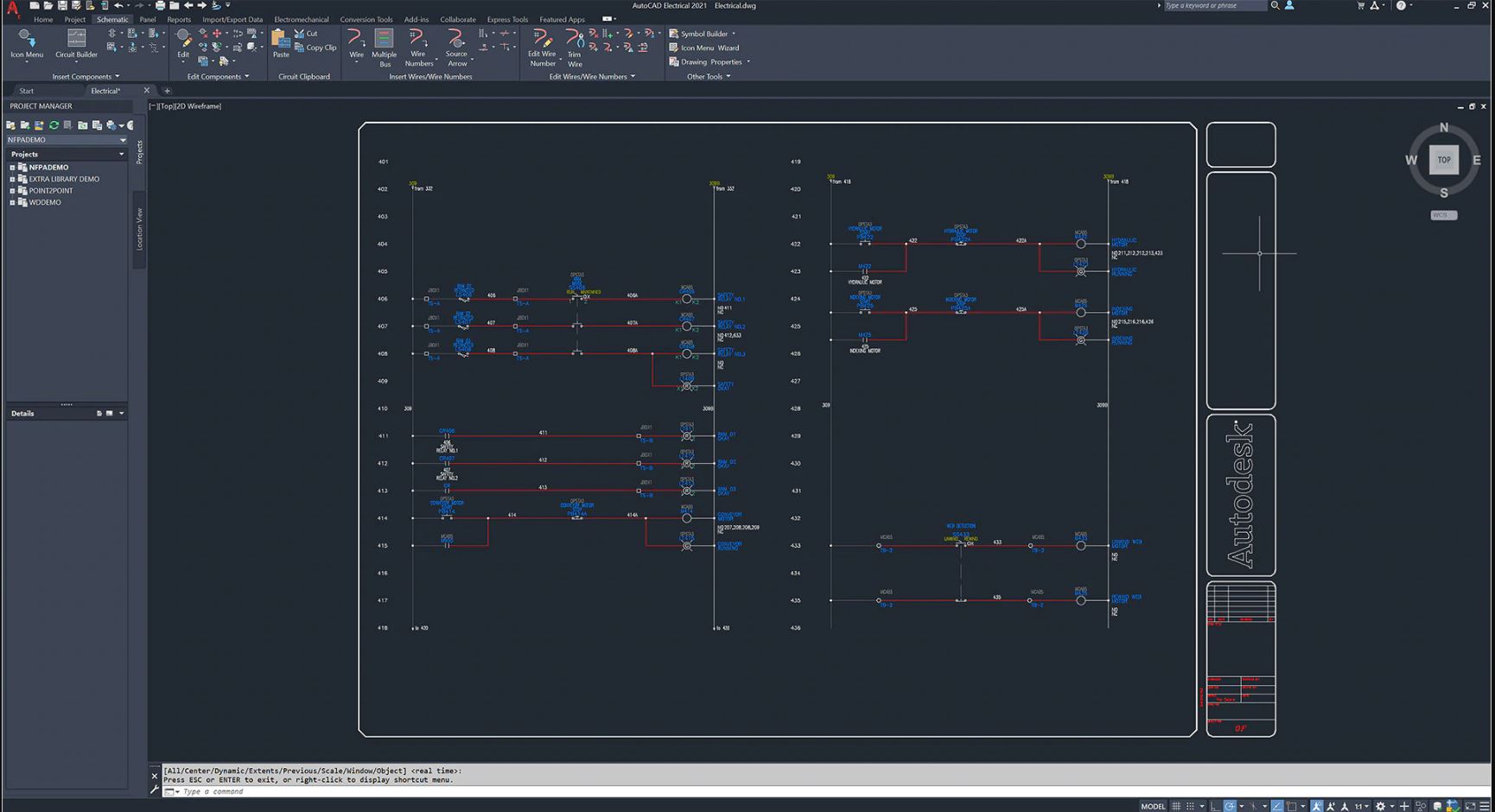

Autocad

Autocad is computer-aided design (CAD) software from Autodesk that is proving to be a very effective basic tool especially for 2D drawing production. It can be useful both in designing complex diagrams and in organizing and optimizing workspaces.

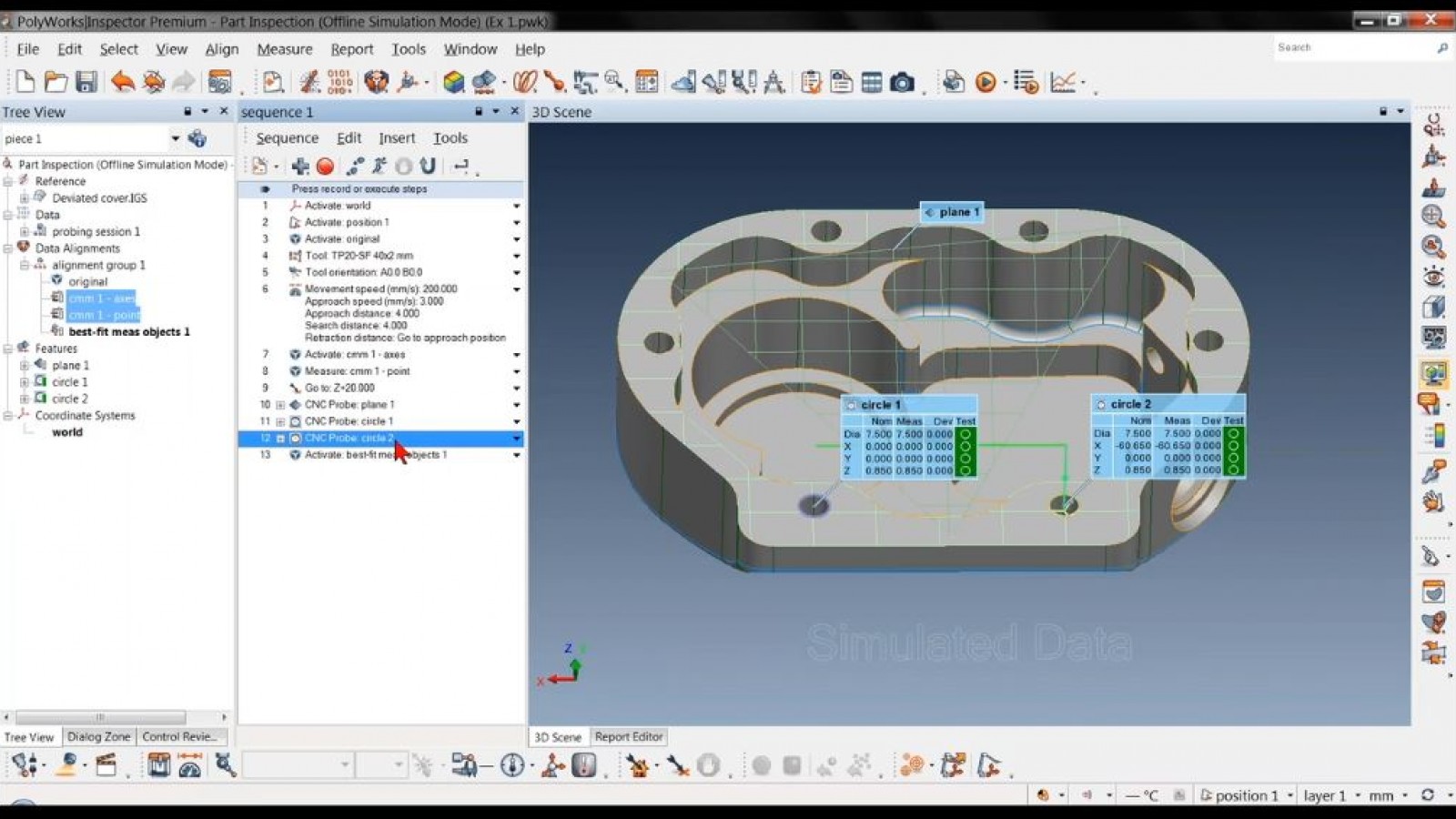

Polyworks Inspector

Polyworks Inspector is a metrological inspection tool. Its use at TOPMED goes hand in hand with the Hexagon Absolute Arm 7 axes for the realization of a dimensional control of high precision.

Polyworks Modeler -

Reverse-engineering Software

Polyworks Modeler is a reverse-engineering tool for extracting polygonal modeling from the digitization of a physical part. It also helps bridge the gap between traditional design and computer-aided design.

Software - Biomechanics Division

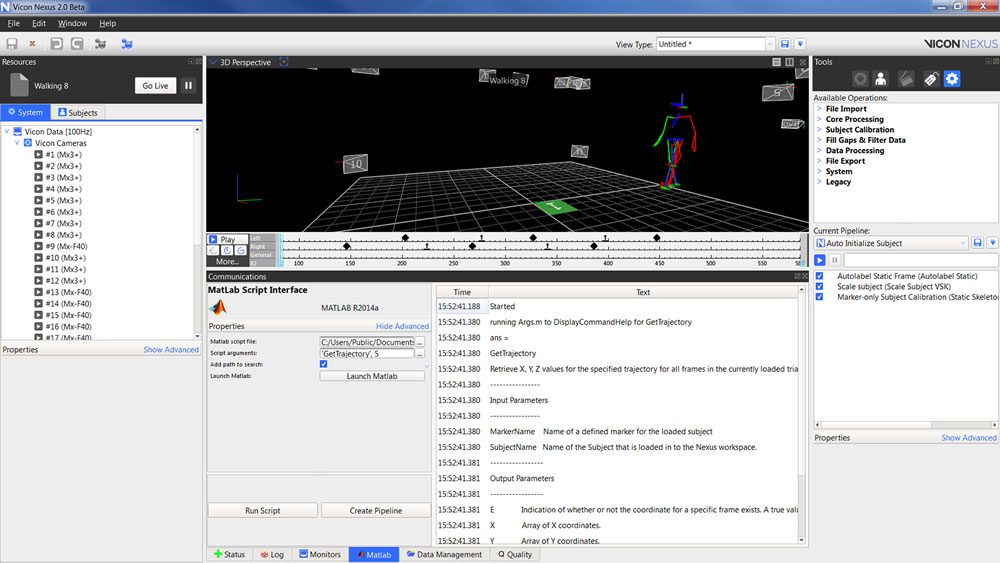

Nexus

Nexus is biomechanical data acquisition and processing software used with the Vicon Vantage camera system. It allows us to digitally reproduce the recorded movements and analyze them and analyze the recorded movements.

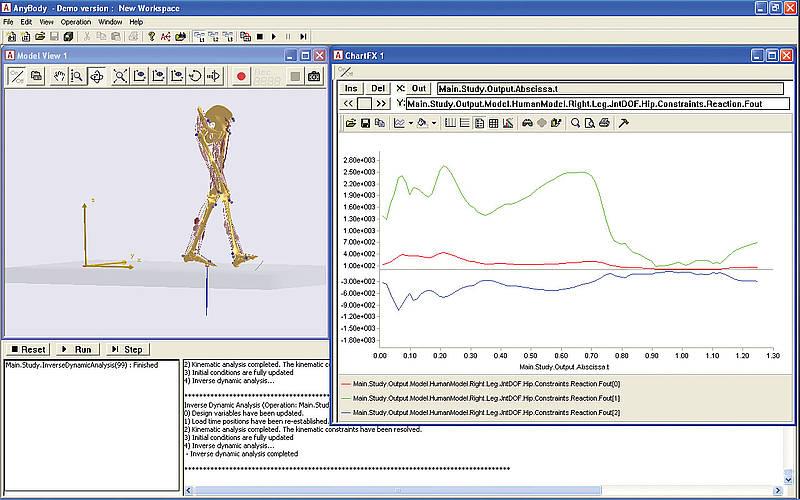

AnyBody Modeling System

AnyBody is an anatomical simulation software that calculates the forces generated in muscle, ligament and bone tissue during movement.

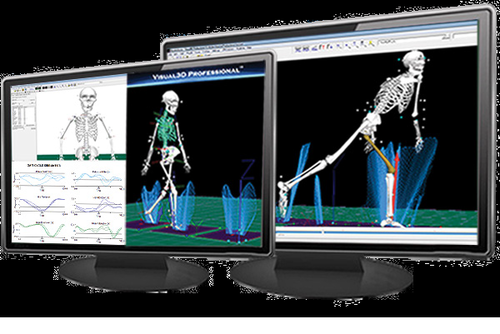

Visual 3D

Visual 3D is a biomechanical modeling software that allows the analysis of movements and the obtaining of kinematic and kinetic measurements.

Matlab

Matlab is a programming and numeric computing platform used to automate the analysis of experimental data of all kinds. This software also makes it possible to present the results in an interesting and innovative way. TOPMED uses this software to produce biomechanical models allowing the calculation of measurements that would not be easily accessible in certain experimental contexts.